There has been a rising pattern in the utilization of pellets for energy. Therefore, the interest in pellet plants is expanding. But when it comes to choosing the right pellet mill, various factors need to be considered. As plenty of options are available by comparing the options on these factors, you can find the right pellet mill.

This blog post will describe the various factors that are required for choosing the pellet mills for your needs. So if you are looking to buy one, stay till the end to find the right one!

Checklist of your requirements

The first and foremost thing required in choosing the right pellet is clearly understanding your requirements. You have to first access the needs that you have. Look for the requirements, like the production capacity you need. Preferred raw material and suitable pellet machine. Moreover, you must check your requirements for the type of pellet you need.

You must analyze all these factors and then make a requirements checklist. In case there is a specific prerequisite, you should add that one to your checklist. You can look at the choices by viewing the checklist and, afterwards, track down the one that suits the requirements.

Types of pellet mills to consider

The one factor that holds prime importance in choosing the right pellet mill is the type of pellet mill. The type of the mill is crucially important as it decides the final product. There are various forms of pellet mills available.

If we talk about them one by one, firstly, we have the flat die pellet mill. It has horizontally attached dies and rollers, so you can get the designs only in the horizontal dimension. The flat die pellet mill is mostly used in small factories or in small-scale production areas. The pellets that the flat die pellet mill makes are often used for combustion and heating purposes both on the home and the industrial scale.

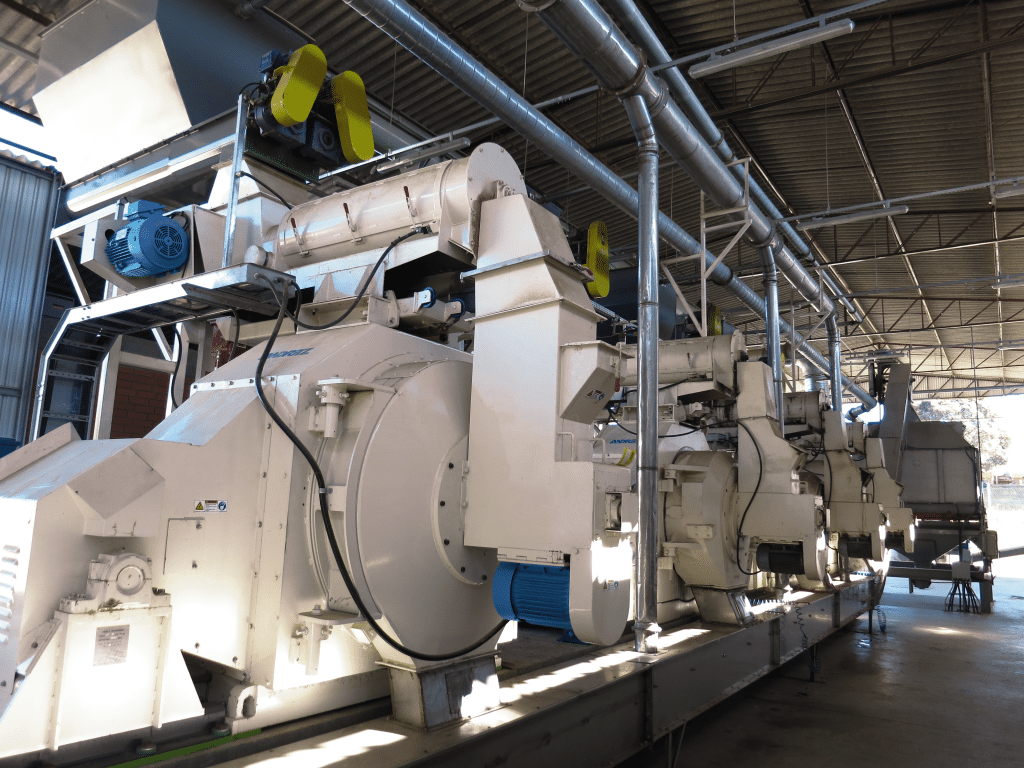

The next type of pellet mill is the ring die pellet mill. The ring die pellet mill has larger vertical die and rollers, so you can make shapes in the vertical dimension compared to the horizontal ones in the flat die mill. In the case of their usage, they are often used in larger production areas, like on the industrial scale.

The next type is the briquette machine; in comparison to the other types, it uses hydraulic pressure technology. And it produces more block-like pellets. It is also commonly used for combustion purposes for heating in homes and industries.

The last one on the list is the small feed pellet mills. They are made up of small farms that produce pellets for animal feed, whether a fish farm or a livestock farm.

Production capacity

The one factor that needs to be considered is the production capacity of the pellet mill. Before you continue your search for the perfect mill in terms of production capacity, you must have your desired production idea so you can appropriately choose the one you need.

If you are looking for a pellet mill on a small scale, then a flat die pellet mill is a decent choice as it has a production range from 100 kg/h to 700 kg/h/. So, it is the right option for a small-scale industry to be a home industry. The ring dies pellet mill has a larger production capacity and is often used on a larger scale in big industries. The production range is 600 kg/h to 2000 kg/h. The higher production range and output make it very much suited for larger scale.

Talking about the other ones, we have the small feed pellet, which can be utilized for the medium and small scales. In the range terms, the production is 600 kg/h to 1000kg/h. Lastly, we have the briquette mills. They have varied ranges, and their range of production commonly depends on the size of the mill.

Raw material and the pellet quality

The next thing that is important for consideration is the raw material that can be used and the quality of the pellet that the mill will provide.

The raw material used for flat die pellet mills is commonly the residues of wood products, sawdust, and other residues from the agriculture sector. In terms of the quality of the pellet, the compression ratio is slightly less in comparison to the others, but it can provide you with decent density and overall quality.

You can use wood and agricultural residue for the ring die pellet mill, but you can also use biomass, providing you with a large range of raw materials. In the quality parameters, it gives superior density and compression compared to the other, and as it provides consistent density, it is recommended for larger industries.

For the small feed pellet mills, the raw material that is best suited is the grains, soybeans and the materials often used for pellet feed production. It is not suited to biomass and wood. And they are particularly for the feed production of the animals. They provide quality feed that has the utmost nutrition for poultry livestock and aquaculture.

The briquette machines can handle various types of materials, from wood sawdust and residues from agriculture and industries. They are usually used for their particular block, like pellets, that are different from the traditional pellets. They produce pellets that are quite durable, and therefore, for combustion use, they are recommended.

Maintenance and budget

Talking about the maintenance and the budget of the mills, they are of equal importance as the other elements of consideration.

Talking about the flat die one, it needs moderate maintenance, and as it is operated on a smaller scale and with less production capacity, they are relatively cheaper. On the other hand, the ring dies are used for a larger scale, and thus, they need higher initial investment. As they have a complex procedure, they also need a high level of maintenance. Small feed is cost-effective and low-maintenance for farmers. And on the last, the briquette maintenance and the budget vary on the design type and usage.

Have any questions regarding the topic Perfect Pellet Mill for Your Needs? Feel free to comment below.

Also Read: A Blog Differentiating Small and Comprehensive Wood Chippers