In the realm of biomass pellet production, the Triple Pass Rotary Drum Dryer stands as a revolutionary innovation, redefining the efficiency and quality standards of the drying process. With its unique design and mechanism, this dryer offers unparalleled advantages that contribute to higher yields and superior pellet quality.

Introduction

Biomass pellets hailed as a sustainable energy source, are derived from organic materials such as wood, agricultural residues, and even dedicated energy crops. The production of these pellets involves several essential steps, with drying being a pivotal stage that directly influences the final product quality.

The Need for Effective Drying

Drying biomass materials is crucial as it reduces moisture content, which is essential for both storage and combustion efficiency. High moisture content not only leads to mold growth but also lowers the energy content of the pellets. Hence, a reliable and efficient drying method is paramount.

Revolutionizing Drying with Triple Pass Rotary Drum Dryer

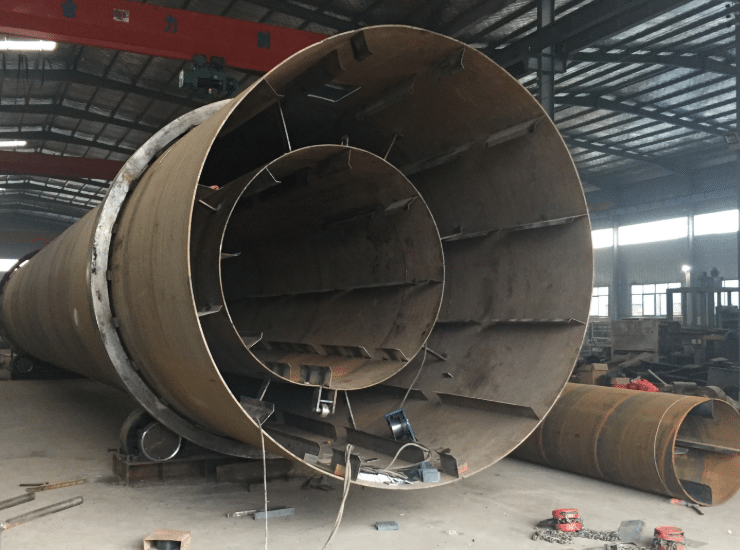

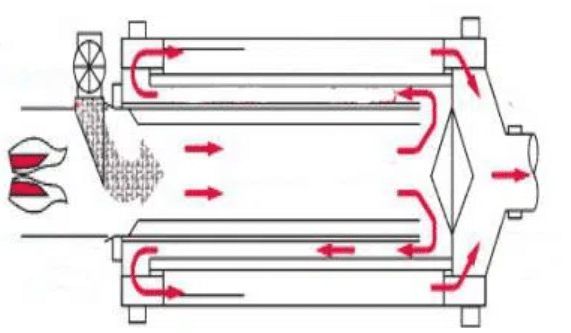

The Triple Pass Rotary Drum Dryer is a game-changer in the biomass pellet production process. Its innovative design comprises three concentric cylinders through which the biomass materials pass. Each cylinder serves a distinct purpose in the drying process, contributing to its exceptional efficiency.

How It Works

- First Pass: In the innermost cylinder, the wet biomass materials enter. Here, they are exposed to high-temperature air generated by a burner. The heat efficiently evaporates surface moisture, kickstarting the drying process.

- Second Pass: The partially dried materials move to the second cylinder, where they encounter medium-temperature air. This stage facilitates the extraction of moisture from the material’s core, ensuring uniform drying.

- Third Pass: Finally, the materials enter the outermost cylinder, where they are met with low-temperature air. This gently dries the materials to their required moisture level, enhancing their quality for pellet production.

Advantages of Triple Pass Rotary Drum Dryer

- Unmatched Efficiency: The triple pass design maximizes heat utilization, resulting in rapid and thorough drying. This significantly reduces energy consumption compared to traditional dryers.

- Superior Pellet Quality: By ensuring consistent and thorough drying, the dryer contributes to pellets with uniform moisture content. This uniformity translates to enhanced combustion efficiency and reduced emissions.

- Enhanced Throughput: The innovative design and optimized airflow enable higher material throughput, allowing for increased pellet production capacity.

- Energy Savings: The efficient use of heat not only speeds up the drying process but also minimizes energy wastage, making the production process more environmentally and economically sustainable.

- Reduced Footprint: The compact design of the triple pass dryer means it occupies less space compared to other drying methods, making it suitable for facilities with limited room.

Conclusion

In the world of biomass pellet production, every stage of the process plays a critical role in determining the quality and efficiency of the final product. The Triple Pass Rotary Drum Dryer emerges as a revolutionary solution to the challenges posed by traditional drying methods. Its innovative triple pass design, efficient heat utilization, and superior drying capabilities make it an indispensable asset in enhancing pellet quality, production capacity, and energy efficiency. As the demand for biomass pellets continues to grow, embracing such cutting-edge technologies becomes not just a choice, but a necessity for producers aiming to stay ahead in this dynamic industry.